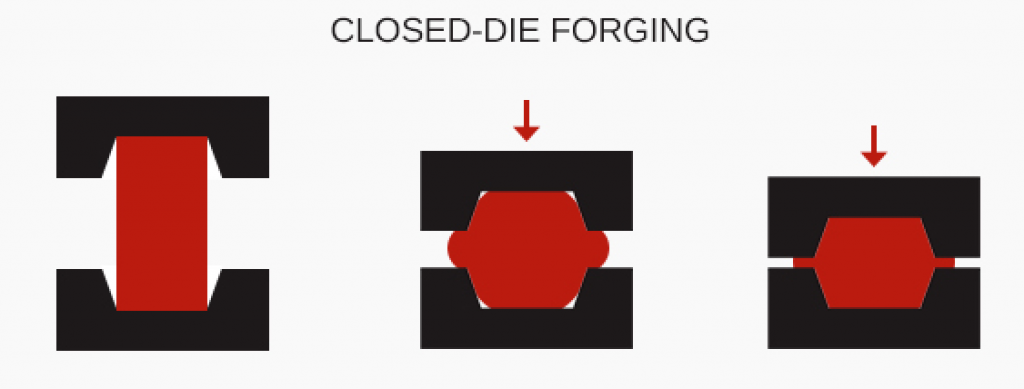

Core Tip: The basic steps of die forging design are as follows:

①Understand the parts drawings and data, understand the parts materials and pavilion-shaped structure, usage requirements, assembly relationships, and mold line templates.

②Consider the part structure

The basic steps of die forging design are as follows:

①Understand the parts drawings and data, understand the parts materials and pavilion-shaped structure, usage requirements, assembly relationships, and mold line templates.

②Considering the rationality of the die forging process of the part structure put forward suggestions for improvement and negotiations.

③ Coordinate the process requirements of hot and cold processing, such as processing benchmarks, process bosses, machining allowances, etc.

④Analyze and determine the die forging method and the position of the die.

⑤ Draw forging graphics, find and solve problems such as size inconsistency.

⑥Add the machining allowance, determine the die forging inclination, fillet radius, cavity shape, and main dimensional tolerances, check the wall thickness requirements, and consider the various process and physical and chemical test requirements, and finally add notes to improve the die forging drawings.