Forging is a processing method that uses forging machinery to apply pressure to metal blanks to cause plastic deformation to obtain forgings with certain mechanical properties, certain shapes and sizes. It is one of the two major components of forging (forging and stamping). Forging can eliminate defects such as as-cast porosity produced in the metal smelting process and optimize the microstructure. At the same time, due to the preservation of complete metal flow lines, the mechanical properties of forgings are generally better than castings of the same material. For important parts with high loads and severe working conditions in related machinery, forgings are mostly used, except for plates, profiles or weldments that can be rolled with simpler shapes.

It can be understood that forging is a processing method in which iron blocks are heated or not heated and formed under the action of force. Commonly known as strike iron.

Deformation temperature of forged material

The starting recrystallization temperature of steel is 800°C as the dividing line, hot forging is higher than 800°C; warm forging or semi-hot forging is called between 300 and 800°C, and cold forging is called forging at room temperature. The forgings used in most industries are hot forging. Warm forging and cold forging are mainly used for forging parts such as automobiles and general machinery. Warm forging and cold forging can effectively save materials.

Type of forging

According to the forging temperature, it can be divided into hot forging, warm forging and cold forging.

According to the forming mechanism, forging can be divided into free forging, die forging, ring rolling and special forging.

- Free forging. Refers to the processing method of using simple general-purpose tools or directly applying external force to the blank between the upper and lower anvils of the forging equipment to deform the blank to obtain the required geometric shape and internal quality of the forging. The forging produced by free forging method is called free forging. Free forging mainly produces forgings with small batches. Forging equipment such as forging hammers and hydraulic presses are used to form blanks to obtain qualified forgings. The basic process of free forging includes upsetting, drawing, punching, cutting, bending, twisting, shifting and forging. Free forging adopts hot forging method.

- Die forging. Die forging is divided into open die forging and closed die forging. Metal blanks are deformed under pressure in a forging die chamber with a certain shape to obtain forgings. Die forging is generally used to produce parts with small weight and large batches.

- Die forging can be divided into hot forging, warm forging and cold forging. Warm forging and cold forging are the future development direction of die forging, and also represent the level of forging technology. According to the material, die forging can also be divided into ferrous metal die forging, non-ferrous metal die forging and powder product forming. As the name suggests, the materials are ferrous metals such as carbon steel, non-ferrous metals such as copper and aluminum, and powder metallurgy materials. Extrusion should be attributed to die forging, which can be divided into heavy metal extrusion and light metal extrusion. It should be noted that the billet cannot be completely restricted. For this reason, the volume of the billet should be strictly controlled, the relative position of the forging die should be controlled and the forging should be measured, and efforts should be made to reduce the wear of the forging die.

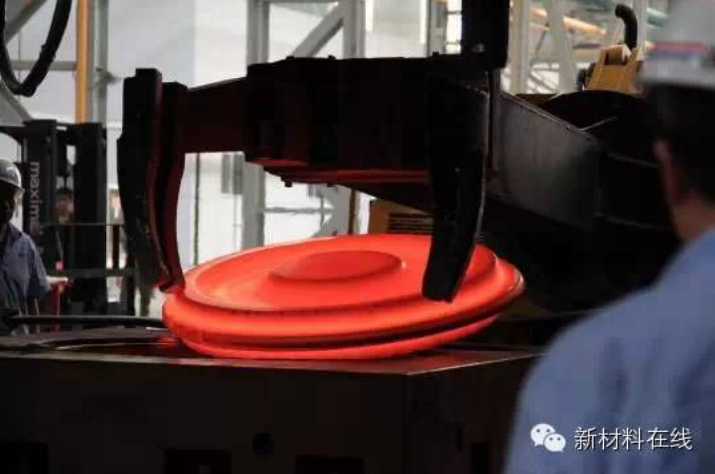

- Grinding the ring. Ring rolling refers to the production of ring parts of different diameters through special equipment ring rolling machines, and is also used to produce wheel-shaped parts such as automobile wheels and train wheels.

- Special forging. Special forging includes roll forging, cross wedge rolling, radial forging, liquid die forging and other forging methods, which are more suitable for the production of parts with special shapes.

For example, roll forging can be used as an effective preforming process to greatly reduce the subsequent forming pressure; cross wedge rolling can produce steel balls, transmission shafts and other parts; radial forging can produce large forgings such as barrels and stepped shafts.

Die forging

According to the movement mode of the forging die, forging can be divided into pendulum rolling, pendulum swivel forging, roll forging, cross wedge rolling, ring rolling and cross rolling. Rotary rolling, pendulum swivel forging and ring rolling can also be processed by precision forging. In order to improve the utilization rate of materials, roll forging and cross rolling can be used as the pre-process processing of slender materials. Rotary forging, like free forging, is also partially formed, and its advantage is that compared with the size of the forging, it can be formed even when the forging force is small. In this forging method including free forging, the material expands from the vicinity of the die surface to the free surface during processing, so it is difficult to ensure the accuracy. Therefore, the movement direction of the forging die and the swivel forging process are controlled by a computer, which can be used at a lower cost. The forging force is used to obtain products with complex shapes and high precision, such as forgings such as steam turbine blades with many varieties and large sizes.

The mold movement and degree of freedom of the forging equipment are inconsistent. According to the deformation limitation characteristics of the bottom dead center, the forging equipment can be divided into the following four types:

1. The form of limiting forging force: the hydraulic press that directly drives the slider by hydraulic pressure.

2. Quasi-stroke limitation method: hydraulic press with crank-link mechanism driven by hydraulic pressure.

3. Stroke limitation method: mechanical press with crank, connecting rod and wedge mechanism driving slider.

4. Energy limiting method: use the screw and friction press of the screw mechanism. In order to obtain high precision, attention should be paid to prevent overload at the bottom dead center, control speed and die position for heavy-duty aviation die forging hydraulic press. Because these will have an impact on forging tolerances, shape accuracy and forging die life. In addition, in order to maintain the accuracy, attention should also be paid to adjusting the clearance of the slider guide rail, ensuring the rigidity, adjusting the bottom dead center and using the auxiliary transmission device and other measures.

Forged slider

The forging slider has vertical and horizontal motion (for forging of slender parts, lubrication cooling and forging of parts for high-speed production), and the compensation device can increase the motion in other directions. The above-mentioned methods are different, and the forging force, process, material utilization rate, output, dimensional tolerance, and lubrication and cooling method required to successfully forge the first large disc product are different. These factors are also factors that affect the level of automation.

Material for forging

Forging materials are mainly carbon steel and alloy steel with various components, followed by aluminum, magnesium, copper, titanium and their alloys. The original state of the material is bar stock, ingot, metal powder and liquid metal. The ratio of the cross-sectional area of the metal before deformation to the cross-sectional area after deformation is called the forging ratio. Correct selection of forging ratio, reasonable heating temperature and holding time, reasonable initial forging temperature and final forging temperature, reasonable deformation amount and deformation speed have a great relationship with improving product quality and reducing cost.

Generally, round or square bars are used as blanks for small and medium-sized forgings. The grain structure and mechanical properties of the bar are uniform and good, the shape and size are accurate, the surface quality is good, and it is convenient to organize mass production. As long as the heating temperature and deformation conditions are controlled reasonably, forgings with excellent performance can be forged without large forging deformation. Ingots are only used for large forgings. The ingot is a cast structure with large columnar crystals and a loose center. Therefore, it is necessary to break the columnar crystals into fine grains through large plastic deformation, and loosen and compact them to obtain excellent metal structure and mechanical properties. The powder metallurgy preform formed by pressing and sintering can be made into powder forging by flash-free die forging in a hot state. Forging powder is close to the density of general die forgings, has good mechanical properties, and high precision, which can reduce subsequent cutting processing. The internal structure of powder forging is uniform without segregation, so it can be used to manufacture small gears and other workpieces.

However, the price of powder is much higher than that of general rods, and its application in production is limited. Apply static pressure to the liquid metal poured in the die cavity to make it solidify, crystallize, flow, plastically deform and form under the action of pressure, and the die forging with the required shape and performance can be obtained. Liquid metal die forging is a forming method between die casting and die forging, especially suitable for complex thin-walled parts that are difficult to form by general die forging. In addition to the usual materials for forging, such as carbon steel and alloy steel of various components, followed by aluminum, magnesium, copper, titanium and their alloys, iron-based superalloys, nickel-based superalloys, cobalt-based superalloys The deformed alloys are also completed by forging or rolling, but these alloys are relatively difficult to forge due to their relatively narrow plastic zone. The heating temperature, starting forging temperature and final forging temperature of different materials have strict requirements.

Forging process

Different forging methods have different processes, among which the hot die forging process is the longest, the general sequence is: forging billet blanking; forging billet heating; roll forging billet preparation; die forging forming; trimming; punching; correction; Intermediate inspection, check the size and surface defects of forgings; heat treatment of forgings, to eliminate forging stress and improve metal cutting performance; It must go through chemical composition analysis, mechanical properties, residual stress and other inspections and non-destructive testing.

Forging Features

Compared with castings, metal can improve its structure and mechanical properties after forging. Due to the deformation and recrystallization of the metal after the casting structure is thermally processed and deformed by forging, the original coarse dendrites and columnar grains become equiaxed recrystallized structures with finer grains and uniform sizes, so that the original segregation, The compaction and welding of porosity, pores, slag inclusions, etc. will make the structure more compact and improve the plasticity and mechanical properties of the metal. The mechanical properties of castings are lower than those of forgings of the same material. In addition, the forging process can ensure the continuity of the metal fiber structure, so that the fiber structure of the forging is consistent with the shape of the forging, and the metal streamline is complete, which can ensure that the parts have good mechanical properties and long service life. Precision die forging, cold extrusion Forgings produced by processes such as warm extrusion and warm extrusion are all incomparable to castings.

Forgings are objects in which metal is pressured and plastically deformed to shape the required shape or a suitable compression force. This force is typically achieved through the use of a hammer or pressure. The forging process creates a refined grain structure and improves the physical properties of the metal. In the actual use of components, a correct design can make the particle flow in the direction of the main pressure. Castings are metal shaped objects obtained by various casting methods, that is, the smelted liquid metal is poured into the pre-prepared mold by pouring, injection, suction or other casting methods, and after cooling, it is sanded, cleaned and finished. Processing, etc., the resulting object has a certain shape, size and performance.

Forging level analysis

China’s forging industry has developed on the basis of introducing, digesting and absorbing foreign technologies. After years of technological development and transformation, the technological level of leading enterprises in the industry, including process design, forging technology, heat treatment technology, machining technology, Detection and other aspects have been greatly improved.

(1) Advanced process design manufacturers have generally adopted thermal processing computer simulation technology, computer-aided process design and virtual technology, which has improved the level of process design and product manufacturing capabilities. Introduce and apply simulation programs such as DATAFOR, GEMARC/AUTOFORGE, DEFORM, LARSTRAN/SHAPE and THERMOCAL to realize computer design and process control of thermal processing.

(2) Forging technology Most hydraulic presses of 40MN and above are equipped with 100-400t.m main forging manipulators and 20-40t.m auxiliary manipulators. A considerable number of manipulators are controlled by computers, realizing the comprehensive control of forging process , so that the forging accuracy can be controlled at ±3mm, and the on-line measurement of forgings adopts laser dimension measuring devices.

(3) The focus of heat treatment technology is to improve product quality, improve heat treatment efficiency, save energy, and protect the environment. For example, computer is used to control the heating process of heating furnace and heat treatment furnace, and the burner is controlled to realize automatic adjustment of combustion, furnace temperature adjustment, automatic ignition and heating parameter management; waste heat utilization, heat treatment furnace equipped with regenerative combustion chamber, etc.; Polymer quenching oil tank with effective cooling control, various water-based quenching media gradually replace traditional quenching oil, etc.

(4) The proportion of CNC machine tools in the machining technology industry is gradually increasing. Enterprises in some industries have machining centers and are equipped with proprietary processing machinery according to different types of products, such as five-coordinate machining centers, blade processing machines, roll mills, Roll lathes, etc.

(5) Quality Assurance Measures Some domestic enterprises have been equipped with the latest testing instruments and testing technologies, using modern automatic ultrasonic flaw detection systems controlled by computers for data processing, and various special automatic ultrasonic flaw detection systems to complete various quality system certifications, etc. . The key production technology of high-speed and heavy-duty gear forging products has been continuously overcome, and industrialized production has been realized on this basis. On the basis of introducing foreign advanced production technology and key equipment, China has been able to design and manufacture high-speed and heavy-duty gear forging production equipment by itself. These equipment are close to the international advanced level. The improvement of technology and equipment level has effectively promoted the domestic forging industry. development of.

The importance of forging

Forging production is one of the main processing methods for providing blanks of mechanical parts in the machinery manufacturing industry. Through forging, not only the shape of mechanical parts can be obtained, but also the internal structure of the metal can be improved, and the mechanical and physical properties of the metal can be improved. Generally, the important mechanical parts with high stress and high requirements are mostly manufactured by forging production method. Important parts such as turbine generator shafts, rotors, impellers, blades, retaining rings, large hydraulic press columns, high-pressure cylinders, rolling mill rolls, internal combustion engine crankshafts, connecting rods, gears, bearings, and artillery in the defense industry are all forged Production. [7] Therefore, forging production is widely used in metallurgy, mining, automobiles, tractors, harvesting machinery, petroleum, chemical industry, aviation, aerospace, weapons and other industrial sectors. Even in daily life, forging production also plays an important role. In a sense, the annual output of forgings, the proportion of die forgings in the total output of forgings, and the size and ownership of forging equipment reflect the industrial level of a country to a certain extent.